bismuth neodecanoate

Overview

Chinese name: bismuth neodecanoate

Chinese alias: bismuth neodecanoate; bismuth neodecanoate (Ⅲ), bismuth neodecanoate, CAS 251-964-6

CAS No:34364-26-6

EINECS number: 251-964-6

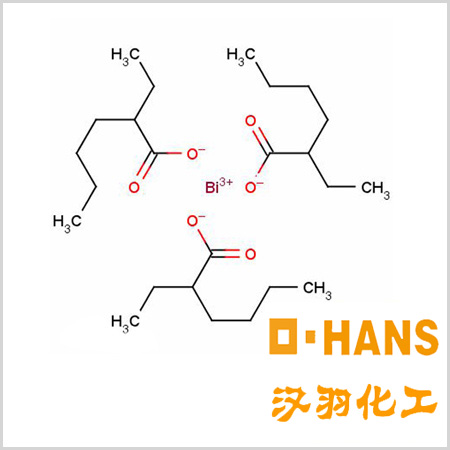

Molecular formula: C30H57BiO6

Boiling point: 256.2 °C at 760 mmHg

Flash point: 114.1 °C

Density: 1.15

Water solubility: insoluble in water

Appearance light yellow liquid

bismuth neodecanoate CAS 251-964-6

Function and use

Safety instructions: S23; S24/25 bismuth neodecanoate is used as a catalyst in the polyurethane industry, showing high catalytic activity, widely used in spraying, high-density elastomers, and microporous elastomer systems.

Has the following characteristics:

Bismuth neodecanoate is a powerful gel catalyst, which promotes the completion of the reaction later

It shows the delayed system viscosity when the level of intermolecular reaction is low at the beginning of the reaction;

Environmentally friendly products that can replace catalysts containing lead and tin;

In ordinary polyurethane reaction systems, microporous elastomer systems and high-density semi-rigid foam systems enhance the stability of system reactions.

Bismuth neodecanoate 251-964-6

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse

package:

180KG/drum Storage: It is recommended to store in a dry and cool area with proper ventilation. After the original packaging, please fasten the packaging cover as soon as possible to prevent the water and other substances from mixing into the product and affecting its performance.

| Company Name: | Shanghai OHANS Chemical Co., Ltd. |

| Sales Manager: | Hunter |

| E_Mail: | Honda@ohans.com |

| Telephone: | +86-021-5161 9971

+86-021-5161 9972 +86-021-5161 9973 |

| Address: | 709 Lingshi Road, Zhabei District, shanghai, China |

| Website: | www.dpta.vip |

PU catalyst: MB20 CAS#: 34364-26-6

Overview:

Common Name: BISMUTH NEODECANOATE

Other Chemical Names: Neodecanoicacid,bismuth(3+)salt;neodecanoicacid,bismuth(3++)salt;BISMUTHNEODECANOATE;BISMUTH(III)NEODECANOATE;bismuth(3+)neodecanoate;BISMUChemicalbookTHNEODECANOATE,TECH;Bismuth(III)neodecanoate,superconductorgrade~60%inneodecanoicacid(15-20%Bi);Bismuth(III)neodecanoate,superconductorgrade

- a) Appearance and Properties: Liquid

Color: light yellow transparent

- b) Boiling point, initial boiling point and boiling range 180 °C

- c) Flash point 158 °C – closed cup

- d) Evaporation rate No data available

- e) Flammability (solid, gas) no data available

- f) high/low flammability or explosiveness limits no data available

- g) Vapor pressure 0.60mmHg at 21 °C

- h) Vapour density No data available

- i) Density/relative density 1.22 g/cm3 at 25 °C

- j) water soluble insoluble

k)n-octanol/water partition coefficient no data available

- l) Autoignition temperature no data available

- m) Decomposition temperature no data available

- n) Viscosity 50mPa.s at 25 °C

Features and uses:

MB20 is used as a catalyst in the polyurethane industry, showing high catalytic activity, and is widely applicable to spray, high density elastomer, and microcellular elastomer systems. Has the following characteristics:

A powerful gel catalyst to promote the completion of the reaction in the later stage;

It shows that the viscosity of the system is delayed when the level of intermolecular reaction is low in the early stage of the reaction;

Environmentally friendly products that can replace lead and tin-containing catalysts;

In the common polyurethane reaction system, the microcellular elastomer system and the high-density semi-rigid foam system enhance the stability of the system reaction.

Acts as a co-catalyst with a tertiary amine to accelerate the urethane reaction and cure. Exhibits delayed viscosity build on front-end at low usage level while promoting excellent back-end cure. It is free of mercury, lead and dibutyl tin. Possesses low volatility with little or no odor. It has compatibility with common rigid and flexible foam polyols.

It is an alternative to tin-based catalysts in flexible slabstock, high-density flexible foams, spray, microcellular, and rigid foam systems.

Storage Information

Recommends that our catalysts be stored in a dry and cool area under appropriate ventilation conditions. Each container should be closed tightly to avoid contamination with moisture or other negative influences that could change the products’ performance in the end use.

Package:

25kg/Plastic Drum, 200KG/Steel Drum, 1000kg/IBC DrumOur Company

Since its establishment, the company has adhered to the service tenet of “integrity-based, customer first”, adhered to customer demand as the focus, market-oriented, adhered to technological innovation, management innovation and service innovation, and constantly implemented lean production, refined management, to provide customers with better products and services! The company has its own factory, research and development base, set up a strict scientific quality management system, and constantly committed to technological innovation, product innovation and management innovation, so as to ensure that our products have a certain competitiveness in the same industry. The factory is located in Jining City, Shandong Province, China, covering an area of 500 acres, and the current production capacity of various types of amines is 5,000 to 10,000 tons per year.

Our Advantages

Strict Quality Management

Our company strictly implements ISO9002 quality management standards and has established a complete quality management system to ensure the long-term stability of product quality.

Efficient Service

Our production is efficient and reliable, so we deliver on time and within delivery deadlines. At the same time, our team is always happy to help customers and strive to solve customer problems in a short time.

Competitive Price

We have long-term services in wholesale Polyurethane catalyst and have established long-term and stable cooperative relationships with many retailers and agents to provide our customers with reasonably priced products.

OEM Available

Our employee team has high R&D capabilities, superb design and development capabilities, skilled manufacturing technology, and rich product application experience, and can also meet OEM business needs.throughout the entire industry chain.